Our Services

Elevate the interior of your space with our versatile epoxy flooring solutions. Whether it's a residential garage, basement, commercial space, or industrial setting, our epoxy coatings offer a seamless, durable, and visually striking surface.

Garage Flooring

The beauty of epoxy flooring is that it’s easy to maintain, whether by broom finishing , hosing down the floor, or even just using a blower to keep it clean.

Sidewall Flaking

Depending on the condition of your side walls, you can also epoxy them, which allows for a smooth, beautiful flow-through finish.

Side Wall Rubber

The rubber diamond membrane leaves a clean finish. For example, when you open your car door, if the edge of the door hits the side walls, it’s protected by the rubber, diamond-plated membrane.

Basement Flooring

We also specialize in basement flooring. There are a few options available, such as metallic flooring, which gives the floor a marble-like appearance, or you can choose the basic standard flakes. Both options make the floor look clean and very attractive.

Home Interior Painting

For winter projects we also do interior painting as well basement epoxy finishing.

Here are the steps taken by Eli’s Epoxy Floor Finishing to ensure proper installation and a quality finish:

What’s required is that we grind the floor with an upright machine designed to scrape and level the cement surface using special diamond blades. The same process is applied along the side walls. Once this is done, patching may or may not be required.

All jobs require three (3) coats of epoxy: the base coat, followed by epoxy flakes, and then the top coat of Polyaspartic. This process typically takes 2–3 days, depending on weather conditions, plus an additional 72 hours of drying time before moving anything back into the garage.

Upon approving estimate, this is what's required to prep your garage floor.

You get to pick.

There are more than 30 different variety flakes to choose from with different colours and shapes. This is something that we can show you during the estimate.

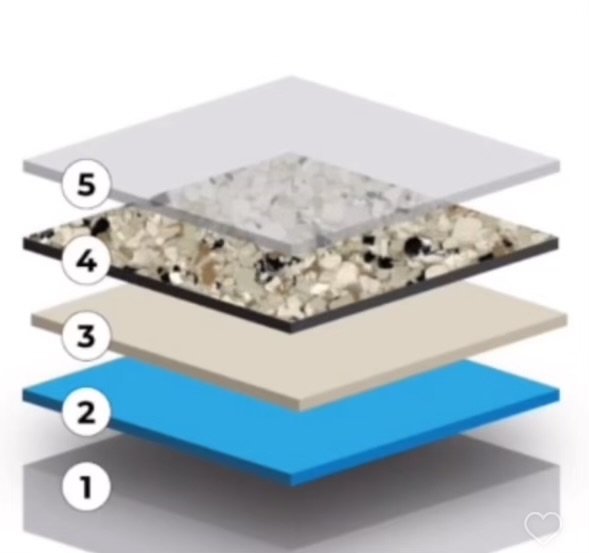

Epoxy Process

The proper process is based on

1) Being the cement floor

2) The first coating of epoxy,

3) Is another layer of epoxy, then apply and broadcast the flakes that you can choose

4) Applying the flakes

5) Is the topcoat this allows it to harden with a protective coating and also has a UV ray protection as well.

You can also purchase a 3 step process which is durable enough. The 4 step is for high traffic volume areas.

Heavy Duty Machine Grinder

In this video, you will see a standup grinding machine with Diamond blades. It is very important to use the right equipment the right hand tools to do the job properly. This gives you a clean, smooth surf area before applying the epoxy product. The old saying is the right tools for the right job.

Concrete Encounter

Eli’s Epoxy Flooring always tests your concrete floor for water damage and moisture. This helps us determine which epoxy product is best for addressing moisture issues. Our epoxy product, called the Waterproof Solution, is a liquid epoxy membrane that locks out moisture for good.

Top Quality Epoxy

It is very important to use top quality, commercial grade epoxy it’s designed for Canadian weather and high volume traffic by using the right epoxy allows you long life and durable floor. The brands that are sold in depot stores are only designed for a few years and do not have a warranty.

By using: Chromology Ottawa a commercial grade product it gives you a better warranty and longer lifespan.